I’ve written before about Design for Logistics: how products themselves can ease or complicate their shipping, or the environmental impact of their packaging. I object to shipping large quantities of fresh air along with the product, and I suppose we all do, but not everything in the world nests together nicely for efficient shipping.

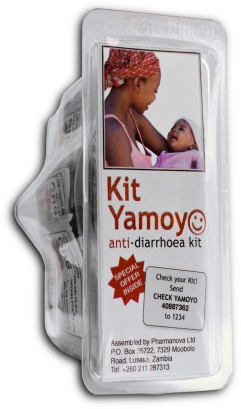

Once in a while, though, there comes along some holistic packaging design that’s so elegant as to take your breath away. If you haven’t already seen it, meet Kit Yamoyo: oral rehydration salts, zinc, soap and a leaflet of instructions for the care of a person with diarrhoea. The outer packaging also serves as measuring device and cup, and – here’s the clever part – it’s shaped to fit in between the bottles in a crate of Coca-Cola.

Inventor Simon Berry had observed that he could get a bottle of Coke just about anywhere, and yet far more important products such as basic medicines weren’t available. Wouldn’t it be possible to piggyback medicines onto the Coca-Cola supply chain? It was an idea that took twenty years and a lot of persistence to realise… but eventually it took off, as a result of social media.

“What about Coca Cola using their distribution channels (which are amazing in developing countries) to distribute rehydration salts? Maybe by dedicating one compartment in every 10 crates as ‘the life saving’ compartment?”

That was Simon Berry’s original Internet posting on the subject, back in 2008. Somewhere along the way, the idea was transmuted: instead of requiring the good folks at Coca-Cola to give up a fraction of their capacity in order to ship the rehydration salts, the innovative design meant that there would be no bottom line impact for purveyors of fizzy drinks. Everybody wins: it generates good press for the Coca-Cola Company (which makes a nice change from their product being criticised for being cheaper than milk)… and children don’t have to die for the want of a simple, cheap treatment.

Although it’s the idea of fitting medicines into the space in a crate that brought the product and the newly-formed Colalife charity to the attention of the media, there are at least two other key components that make this grassroots supply chain work: micro-enterprise, and the use of mobile phones (specifically, SMS messages) to confirm delivery and make payments. Anybody could join in this distribution network – and earn money in the process.

My Supply Chain Management students are already acquainted with Kit Yamoyo: I even made it the subject of one of their exam questions, last year. From a supply chain perspective, I wrote, critically discuss the approach taken, whereby the charity works with microbusinesses rather than simply giving the product away.

Students were divided on this point: some felt that a charity in possession of a life-saving treatment ought to be giving it away… and that’s the kind of aid model that I grew up with, back in the days of Bob Geldof. With a few wealthy sponsors and the assistance of the government, you probably could shift an awful lot of rehydration salts. You could just pitch the things out of the back of low-flying army transport ’plane, or something… but the purpose here wasn’t to deliver a life-saving product once: it was to change the economics of basic medicines fundamentally and permanently. With the ‘AidPod’ as a commercial product (albeit as inexpensive as possible) it gets treated differently. Stocking it at a sensible level is incentivised: tracking, and avoiding spoilage and pilfering becomes everybody’s concern. Manufacturing more ‘AidPods’ becomes something that companies want to do… and at some point between now and 2020, the whole venture becomes commercially sustainable.

Funny thing is, having created an award-winning package, Colalife are largely turning away from that design: a survey revealed that only 8% of retailers made use of crates of Coke to carry the kits. (Elsewhere in their published stats, Colalife report that they found just 4% of kits actually went into a Coca-Cola crate.)

In an effort to drive down the cost of Kit Yamoyo still further, a regular plastic ‘jar’ like the kind of thing you and I get peanut butter in has been tried… with the clever packets that fill the voids in drinks crates not entirely being phased out, but becoming rarer in the future.

“It was the space in the market, not the space in the crates that was important,” Colalife say. The Colalife website reports that approximately 60,000 Kit Yamoyos have been sold to date. Academics estimate that three lives have been saved per thousand kits used: if that’s correct, well… do the maths. While I was trying (and failing) to persuade the fishing industry to use crates made out of Pykrete, the Colalife team were saving dozens of lives – and they’re still ramping up the operation.

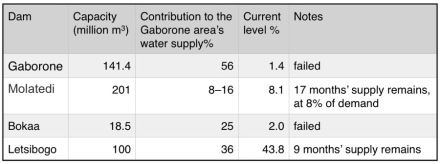

Let’s finish with what might be a particularly relevant message for our new MSc Supply Chain students in Botswana, Malawi, and Zambia:

“You can get any commodity/service to anywhere in the world by creating & sustaining demand & making it profitable to supply that demand.” – Simon Berry (Twitter: @51m0n)