We’ve heard recently that the ocean gyres where waste plastic is accumulating are larger than we thought, and plastic particles are now showing up in just about everything. Some believe that by 2050 there could be more plastic in the sea than fish. We’re getting in a bit of a pickle, here.

Albatross chicks are starving to death, their stomachs filled with plastic waste. This is just one consequence of our love affair with plastics.

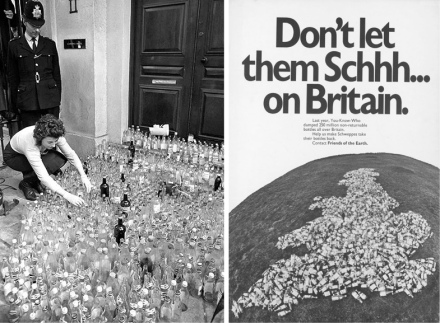

The UK can no longer avoid addressing its waste problems by exporting material to China: the government of the People’s Republic has brought in a ban, and already material is backing up in UK waste facilities. If 500,000 tonnes of waste plastic can no longer be sent ‘away’, what will happen to it?

In the short term, local authorities are going to find that disposal becomes very expensive. The UK waste industry simply doesn’t have the capacity to process the waste that will no longer go to China – and probably won’t have for several years.

In January, UK Prime Minister Theresa May announced a plan to eliminate the UK’s plastic waste by 2042, but can we really spare a quarter of a century before we go closed-loop and/or plastic free? You’d be forgiven for thinking that a quarter of a century suggests a parliament cynically kicking the can on down the road instead of getting to grips with the problem. Where is the roadmap for eliminating plastic waste? How will it be done? What might be the first piece of the puzzle has been revealed today, with the news that we can expect a deposit scheme for drinks bottles.

The European Union also has a strategy for plastics but it’s absolutely brand new – adopted on January 16th, 2018. It’s better than the goal for the UK in that it sets a closer target (2030) but thus far their documents appear to be very informative in detailing the problems, but far less specific in setting out solutions.

Personally, I think that one key element of a future in which we aren’t drowning in our own plastic waste is for bioplastic to become the norm – not just for big corporations with secret recipes in shiny steel vats, but for ordinary small businesses.

Where is the open-source recipe for a bio-based plastic that allows small businesses to replace their petroleum-based plastic products with something made from food waste, or agricultural byproducts?

By way of conducting a straw poll, I opened Apple’s ‘Maps’ application, centred on my home town, and used the ‘search’ function. The nearest business with ‘bioplastic’ in its name… was in Rome. I tried ‘biopolymer’ instead… and found a business in Montabaur, Germany. ‘Biobased?’ … three businesses in the Netherlands. In my neighbourhood it appears that the bioplastic revolution is going to be a long time coming.

I’ve been searching for something that would enable a grassroots bioplastic industry since 2014. Admittedly, it’s only an occasional hobby and not a research project as such, but I’ll try any homebrew bioplastic recipe I can find.

My latest web search revealed one that I’d never heard of before, made from banana peel. Needless to say, I added the ingredients to my weekly shopping.

The recipe comes to us courtesy of Achille Ferrante, and a Youtube video that you can see here. To summarise, you blend some banana peel, mix with water and boil for five minutes. You drain off the excess water, and then combine with vinegar, cinnamon, thyme and honey. A second application of heat brings about polymerisation, after which you squeeze the mixture into flat sheets and then dry it.

I undertook the procurement phase from memory, and bought parsley instead of thyme. (I blame Simon and Garfunkel.) Fortunately, we had some thyme in the house already, so I was able to proceed with the experiment. (The thyme is there as an anitfungal agent, something that I think is a highly desirable component: it’s not fun when bioplastic goes bad on you.)

First off, I ate three bananas. No hardship there! Some commenters in the online banana bioplastic community (a niche group if ever there was one) have suggested that the bananas should still be green, as the skins contain more starch at that point. That may be so, but I wasn’t prepared to eat under-ripe fruit. I reckon you could lob some cornflour into the mix if you really thought that more starch was needed, anyway.

Next, I cut up the banana skins, throwing away the ‘woody’ bits at the ends. The rest was blitzed in a blender. The next step in the instructions was to add water, but I found it simpler to put the water straight in the blender, as it made the banana mulch blend more readily. Given that the end result is meant to be a ‘fibrous bioplastic’ I chose not to blitz the banana peels into a complete ‘smoothie’, reasoning that some of its strength would likely come from embedded fibres.

The banana mulch tended to cling to the sides of the blender, defeating my efforts, so I added the water early.

The smell of banana peel smoothie as it simmers is surprisingly good.

The mixture was then simmered on the stove for about five minutes, and could be seen to thicken. When the time was up I strained it, and pressed out as much water as possible. This left a thick paste, which I weighed.

Following the instructions, for each forty grams of banana peel paste I added 20ml of vinegar, a teaspoon of thyme, a teaspoon of cinnamon and a teaspoon of honey. Everything goes in a saucepan and is mixed together over a medium heat.

One of the disappointments about banana peel bioplastic is that it requires quite a lot of ‘real food’ in addition to the waste material.

What I like about banana bioplastic is that it’s all ‘food’. You don’t have to worry about getting hold of a cheap saucepan or baking tray for your experiments, because you’re not using anything toxic. (Remember the milk plastic from my early experiments? To harden that properly you need formaldehyde…)

What I absolutely loved about making banana bioplastic was the smells in the kitchen: bananas, cinnamon, thyme and honey… what’s not to love? (Oh: the vinegar, maybe.) The problem with all this is that unlike a normal kitchen activity you don’t get anything to eat at the end. It may be a good idea to make the bioplastic in parallel with a regular baking activity – not least because then you’d get a hot oven for “free”, reducing the energy invested in the project.

Delicious smells during the final heating phase. Wishing I was making cookies instead of bioplastic…

One obvious problem is that there’s an awful lot of ‘food’ in this bioplastic. Sure, I don’t eat banana skins, but herbs, spices and honey all cost money. Bioplastic made in this way demands a debate very similar to the one about biofuels that are grown in place of food crops: the industry would be difficult to justify on a hungry planet. (Even banana skins have food value as they are fed to pigs in some places.)

There’s also a lot of energy used in the processes I followed, but I won’t worry too much about that on the grounds that we’re doing this for science, and not in volume production. No doubt some efficiencies could be found if this were being made into an industrial process.

Next comes the bit that always makes my heart sink a little: drying time.

You see, where I come from, plastics don’t need to dry: thermoplastics liquefy when you apply heat, and they solidify obligingly when the temperature falls below their melting point. Air drying is not required. Until we can work out a way to substitute plants for petrochemicals without requiring alterations to manufacturing processes, we haven’t really succeeded.

But this is a stovetop bioplastic, so I had to follow the instructions and dry it.

Squish your bioplastic between some baking parchment, and place in the oven at 50°C for… about an eternity, as far as I can tell.

As instructed I put the mixture in the oven at 50°C, for 45 minutes. It was still just a warm, wet mess at this point, so I gave it another half hour. When it still wasn’t dry I switched to fan oven mode, reasoning that this ought to take away the moisture faster. The alleged bioplastic was barely stronger than cookie dough at this point, and my efforts to turn it over produced some breakage. I reshaped some of my test pieces from broken oddments this point, to see how workable it was. I found it to be sticky, but it was possible to shape the material.

Eventually I tired of waiting for the mixture to dry and increased the oven temperature to 100°C (not using the fan function). After half an hour the flat sections were noticeably drier, and had taken on a leathery feel. I turned them over and gave them another twenty minutes, then switched off the oven and left them in overnight.

In the morning, the thin sections were completely dry, but the larger pieces I had shaped were still a bit sticky. That’ll be the honey, I suppose. This would appear to be one of those “thin film” bioplastics, therefore.

I’m pleased to report that the flat samples really are plastic in nature, with flexibility and a surprising amount of resilience. Their fibrous nature seems to come overwhelmingly from the thyme, which can be seen throughout the material, rather like that old woodchip textured wallpaper we used to have in the seventies. In future I might try chopping the thyme up so that it doesn’t introduce so much roughness. Some bioplastic hackers suggest that thyme oil might be better, although this would introduce more moisture, so I think you’d need to experiment to get this right.

I was skeptical about this material: I suspected that I would simply find a mass of fibres, baked into a matrix with the honey acting as a ‘glue’ but I was wrong: the sheet of banana material really does behave like plastic.

When bent, it flops around, showing a surprising amount of flexibility. That honey really has served as a plasticiser. It’s not what I’d call a durable material, but I’d say it’s more durable than I expected. (You won’t be sewing yourself a pair of bioplastic moccasins with this stuff.) Analogy for the purposes of conveying its engineering properties: it’s about as strong as fruit leather. (Funny, that…)

Surprisingly tough, flexible bioplastic. Now, what are we going to do with it?

One highly desirable property is that it smells great! The cinnamon banishes any hint of the vinegar smell that we experienced with the milk plastic.

I don’t know what you’d actually do with this bioplastic, though, and that’s a worry. You could make biodegradable planting pots that turn to compost, maybe… but you can make those out of compressed peat, or even waste paper. That’s got to be better than faffing about with honey, cinnamon and all that cookery. Also, I think you’d need to raise your pest control game if you’re planning on leaving yummy cinnamon bioplastic in your garden…

This is a bioplastic solution still looking for a problem, then. It’s great stuff and I really enjoyed the experiment. I think we can learn a lot by copying the process shown in Achille Ferrante’s video… but we’re not going to start making genuinely useful home-brew toys or gadgets from it.

Readers may have better ideas for applications?

On the day that I made bioplastic, I put at least three plastic bottles in the recycling bin. After a single use, I’m giving away far better materials than I’m able to make from plant matter. Stable, strong, colour-fast petrochemical plastics that (for now) cost very little. Bioplastic still has a long way to go if it’s ever going make inroads into our plastics habit.

Update for October 24th 2018… some seven months later: the banana bioplastic that I made is still about as tough and flexible as before. That’s quite an achievement given how conventional plastics become more brittle over time, as their plasticisers evaporate away. (I haven’t been leaving the stuff in sunlight, though.) There hasn’t been any noticeable shrinkage, and none of the mould growth that has destroyed the products of my other experiments. This one deserves further study – as long as it’s thin sheets of leathery plastic that you are looking for!

‘

‘